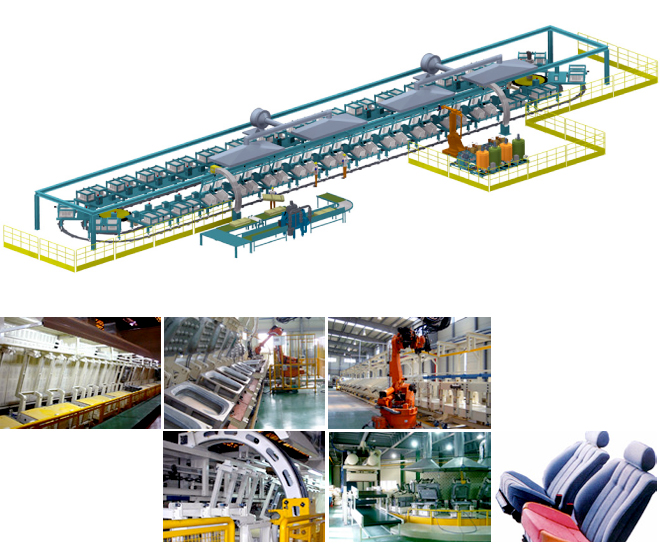

Car seat line

Oval Conveyor Type

THE CONSIST OF SEAT LINE

- High pressure PU foaming machine, 4 comp.

& Mixing Head, MXL-4CD, MXL-4CS - 3sets machine tanks, 250L ~ 500L

- Industrial robot

- Electric control

OVAL CONVEYOR LINE

- Mould carrier & Moulds

- Mould open & Close system

- Mould heating system

- Vacuum crushing machine

- Safety system for working zone

- Gas exhaust and duct system

| TECHNICAL DATA | |

| PU Machine | High pressure machine 4 comp. Mixing head system |

| Production method | Continuous type |

| PU Injection | Automatic pouring into open mould |

| Mould carrier type | 1) Hydraulic open and close 2) Mechanial unit open and close 3) Steel guide bar open and close |

| Mould locking / Unlocking | Locking & Unlocking by air cylinder |

| Mould carrier | 20 ~ 36 Carriers |

| Speed | Approx. 100~200mm/sec, Changeable type |

| Cycle time | Approx. 10~15 sec |

| PU Curing time | Approx. 3.5 ~ 4min |

| Heating unit | 4 kw/h (2carrier / one heating unit), Hot water by electric heating |

| Seat weight | Approx. Min 310g ~ Max 3,200g |

| Seat consists | Front cushion and back, rear cushion and back |