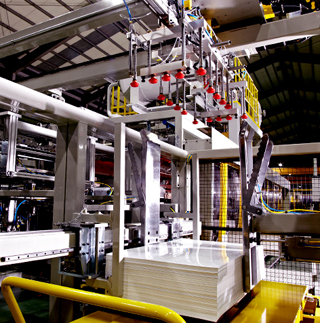

Vacuum thermo forming machine

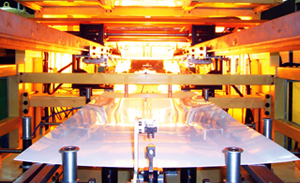

Quartz heating elements for last,

efficient heating of plastic sheets

The advantages of innovative technology

- Precision shuttle type with special raid system

- Without sheet dust with high speed, resisted heating system

- The most effective hydraulic cooling system & heating system

- Patented design, and optimized exhausting and blowing fan system

- Heating system controlled by heating distance heat & sheet by servo motor

- In line concept as more fast processing

time with reliable stocks - In line concept as less noise under 78db

- Less energy and more safety with optimized heating

and raise sensing system - Compact design on special clamp with optimized

shuttle system

Independent heating control

in high accuracy

- Heater controlled by PID

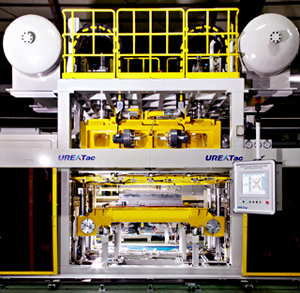

- Safety Features

- In case of fire to process management

- PLC control for personnel & equipment - Clamp (Cooling-Only bar system)

- Forming zone up/down (servo motor)

- Sheet temperature & Blowing

- photo sensor/ control by timer

The compact design with less energy and more safety

The production capacity is within 2 to 5 minutes for the production based on each sheet thickness. It could be adjusted the width of each part separately. It consists of sheet loader, 1 to 2 heating zone, forming zone, piercing and unloading. The heating system is controlled by 100% PID system.

The basic heater is applied to quartz that is controlled independently in high accuracy. The heating room can be consisted as 2 stations (option) and the feedback control system minimizes the surrounding temperature. The foaming zone driven by servo motor is moved by up and down. It also has double sheet check function.

- Air pressure vacuum foaming system

- Double sheet prevention system

- Simple structure design of heating zone

- Stabilized sheet temp' feedback control